Space exploration requires more than brave astronauts. They won't get far without engineers to build their space crafts! Do you think you can build a rocket that could launch astronauts into orbit? Build your engineering skills with this DIY stomp rocket project!

We'd like to thank our longtime friend and corporate partner, FINFROCK for sponsoring this blog!

You Will Need:

- Paper

- Cone and Fin Templates

- Scissors

- Tape

- 3 ½” x 12” pieces of PVC pipe

- 1 ½” x 2” piece of PVC pipe

- 1 ½” x 15” piece of PVC pipe

- 1 ½” PVC Cross Fitting Connector

- 1 ½” 45° PVC Elbow

- 1 ½” 90° PVC Elbow

- 2 ½” PVC End Caps

- 2 Liter Bottles

- Printable Template

Making Your Rocket:

- Tightly wrap your sheet of paper length-wise (so you have a longer rocket rather than a shorter one) around one of the pieces of PVC pipe. The paper should fit snugly around the tube, but not be wrapped so tight that the tube can’t be slid off. Tape the paper tube shut. The entire seam should be covered so that it is airtight. This will be your rocket’s fuselage.

- Cut out the cone template. Bring the straight edges together to create the cone and tape shut. Make sure that entire seam is covered so that it is airtight. If air escapes from the seam in the cone, the rocket won’t launch or won’t go far.

- Tape the cone over one end of the fuselage. Be sure the cone is taped on securely and is airtight. If the cone isn’t on tightly enough or air can escape from this part of the rocket, the cone may fly off the rocket when you try to launch it.

- Now choose how many fins you want and what shape they should be. You can use the templates provided, or make your own.

- Cut out the fins you want. Fold on the dotted line, the tape the small flaps to end of the fuselage opposite the cone. The fins work best when they are evenly spaced and all facing the same way.

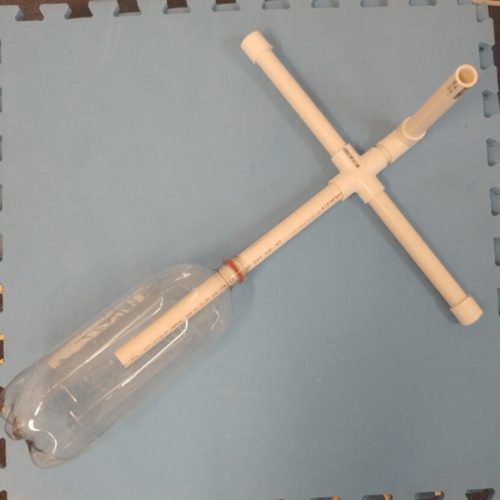

Making Your Launcher:

- Fit 2 of the ½” x 12” pieces of PVC pipe in the cross fitting connector across from each other.

- Place the end caps on these two pieces of PVC pipe to prevent air from escaping through the sides.

- Fit the ½” x 2” piece of PVC pipe in the cross fitting connector between the two longer pieces.

- Attach either the 45° or 90° PVC elbow on the other end of the 2” pipe. The angle of the elbow will determine the launch angle. If you want to launch the rocket straight up, use the 90° elbow. If you want to launch the rocket outwards, use the 45° angle.

- Fit the remaining ½” x 12” piece of PVC pipe in the other end of the elbow. This will be where you place the rocket.

- Fit the ½” x 15” piece of PVC pipe in the remaining opening of the cross fitting connector.

- Tape the 2 liter bottle onto the end of the 15”-long piece of PVC pipe.

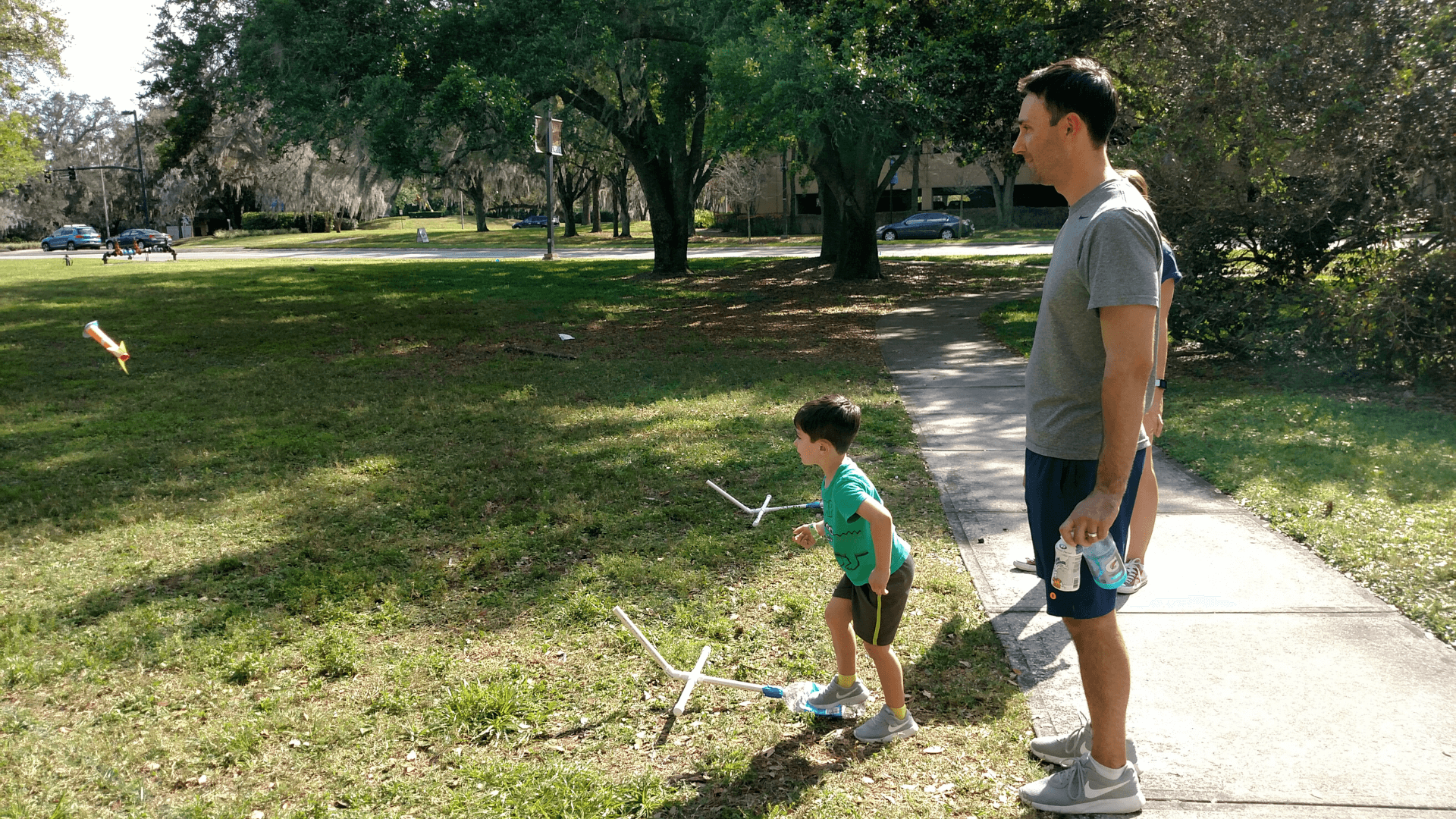

Launching Your Rocket:

- Slide your rocket all the way onto the 12”-long piece of PVC pipe connected to the 45° or 90° elbow.

- Stand next to, not behind, the bottle on your launcher.

- Stomp down or jump on the bottle to launch the rocket.

- To re-inflate the bottle, remove the 15”-long piece of PVC pipe from the cross fitting connector. Blow into the end of the PVC pipe. The bottle will inflate. If the bottle is damaged, it can be removed and a new bottle can be taped on.

Can you make your rocket go higher or farther? What happens if you change the shape and/or number of fins? Make changes to your rocket and launch it again to find out!

Orlando Science Center relies on partnerships with industry experts to provide insight on how science, technology, engineering, and mathematics and the incredible innovators within the industry are pushing the boundaries of possibilities. As a longtime friend and corporate partner, FINFROCK helps us inspire the next generation of STEM professionals and industry leaders. With their commitment and generous support, we are able to bring pivotal technology and engineering learning to life.

FINFROCK is committed to revolutionizing the technological advancement of engineering design and manufacturing. FINFROCK handles the design, manufacturing, and building of hundreds of projects a year for clients throughout Florida and across the nation. Learn more about FINFROCK!